Tool Profile: Dynabrade Dynafile Range

Introduced in 1969, the original Dynabrade Dynafile was intended to replace tedious hand-filing. Since then the design has been improved and refined, with various new models having been released over the last 50 years. These all offer different features suited to various applications, however with so many options to choose from it can make it difficult to know which is the right model for your job. This guide therefore provides a breakdown of the four types of Dynafile and their features.

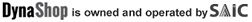

Dynabrade Dynafile I

In the past any intricate sanding in hard to reach areas had to be done by hand, with mixed results due to operator fatigue. The revolutionary Dynafile was conceived on the basis that a powered belt sander with a small contact wheel would be much more effective, offering greatly reduced production times and a more consistent finish.

- The premier tool for machine shops, foundries, aerospace, sheet metal and stamping plants who grind & deburr.

- 4 points of contact ensure the most reliable belt tracking of any tool on the market, with the Dynafile I being the only belt sander to reliably track 3mm wide belts.

- Heavy-duty shroud protects the motor pulley and keeps debris from accumulating on and around the drive wheel.

- Front exhaust ejects excess air directly on to the belt to cool it as it is running, therefore extending belt life by reducing excess heat on the joint.

- Rigid construction improves durability for aggressive grinding on the contact wheel.

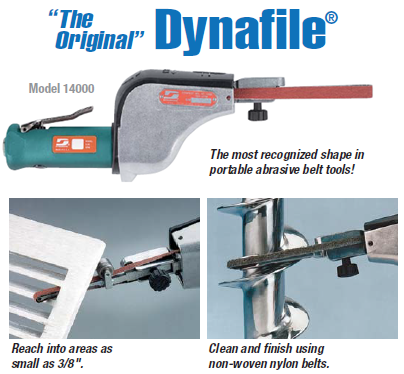

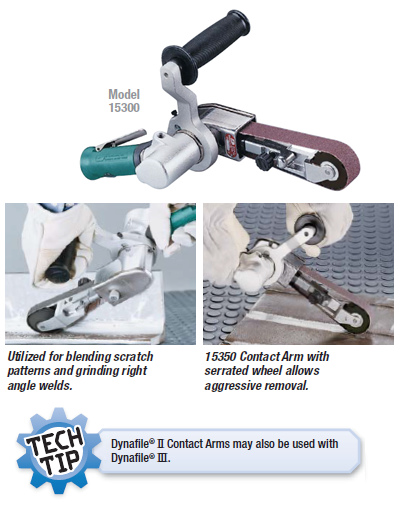

Dynabrade Dynafile II

An evolved version of its predecessor, the Dynafile II was designed with a particular focus on ergonomics during use. It is lighter and offers reduced vibration levels, providing more comfortable operation for the user. In addition this tool is very versatile, with a range of over 25 arms as well as being interchangeable with the Dynafile III selection of contact arms also.

- Wide variety of applications; grind, deburr, blend and polish, on metal, plastic, fibreglass, composites, rubber, glass and more.

- Multi-position grinding head pivots 360° for full rotation and access to hard to reach areas.

- Shorter belt housing offers longer workable reach.

- Tactile, insulated grip for maximum comfort and reduced vibration transfer to the operator.

- Easily converts to die grinder with optional 50010 Collet (1/4″) or 50015 Collet (6 mm).

- Gearless motor for reduced downtime & maintenance.

- Belt guard easily detaches for quick abrasive change, with the simple belt tracking adjustment knob.

As well as the standard models there are several variations available, including:

- Slow-speed version, for grinding titanium and other heat-sensitive exotic alloys.

- Low-profile version, for working in low-clearance spaces.

- Vacuum-capable version, for extracting dust in suitable applications.

- Electric version, in 110V only where an air supply is not available.

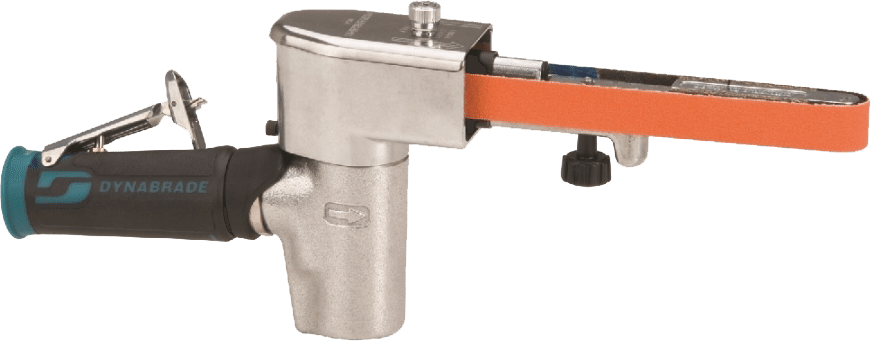

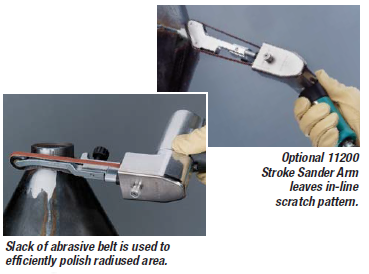

Dynabrade Mini-Dynafile II

Designed to be even more lightweight and ergonomic than the two older models, the Mini-Dynafile II has many of the same features. The key difference however is that it is more compact, and so while the workable reach is reduced due to the shorter length of the contact arms which it can use, it in fact offers greater access to low-clearance areas than where the bodies of the Dynafile I & II would allow.

- Lightweight ergonomic design features 7° offset “soft touch” grip.

- Multi-position grinding head pivots 360°.

- Rear exhaust tool directs some air to front, to cool abrasive belt while running.

- Belt guard easily swivels for quick abrasive change, with the simple belt tracking adjustment knob.

- 11 contact arms available, many of which are offset to make the Mini-Dynafile II ideal for strap-polishing on radiused surfaces.

- Easily converts to die grinder with optional 01644 (1/4″) Threaded Collet Insert.

- Vacuum-capable model available for extracting dust in suitable applications

Dynabrade Dynafile III

- Dynafile® III Abrasive Belt Tool offers all the versatility of the world-famous Dynafile® II, while serving up more power (.7 hp / 522 W) for faster material removal.

- Tool includes high-efficiency Rubber Drive Wheel, ideal for use with all abrasive belts.

- Tool grinding head pivots 360°.

- Soft grip handle assembly allows operator to apply additional force to contact wheel. Handle also offers enhanced control and maneuverability.

- Includes side handle for two-handed use, offering the operator greater control and increasing the pressure that can be applied.

- Range of 8 different contact arms available, as well as being interchangeable with the arms for the Dynafile II.

- Model 15420 Dynafile III includes arm with unique 4″ diameter wheel, for grinding or blending right angle welds and fillet welds with no undercutting.