How to Select A Compressor / Air Supply System

Guidelines for Selecting A Compressor To Meet Your Requirements

A) Compressor Type

– Base on your PSIG (Bar) needs

0 to 80 PSIG (5.5 Bar) – You may only need a single stage compressor.

80 to 250 PSIG (17.2 Bar) – You will need a two-stage compressor.

Two-stage compressors are recommended when tool use is continuous.

Note: Dynabrade air tools require operating air pressure of 90 PSIG (6.2 Bar).

B) Air Consumption

Determine the total demand SCFM (L/Min). List the requirements for all equipment, tools and other air consumption variables (both continuous and intermittent air usage demands).

C) Compressor Horsepower (hp)

Use the determined total demand SCFM (L/Min) and add approximately 20% for system variables.

Add ______% for (your) future growth.

If the above total equals less than 100 SCFM (2,832 L/Min) divide this total by 4 to find the compressor hp.

If the total is over 100 SCFM (2,832 L/Min) divide by 5 to find the compressor hp.

Example: System requirements = 165 SCFM (4,673 L/Min) @ 100 PSIG (6.9 Bar)

165 ÷ 5 = 33 hp

Resulting in a suggested compressor size:

30 hp to 40 hp compressor

Calculator Your Required Compressor Size (HP)

D) Tank Size

As a general rule, the larger the tank, the better the system. Use a larger tank for installations where large flows

of short duration are needed.

Example: For a 5 hp compressor use a 60 Gal. (227 L), 80 Gal. (303 L) or 120 Gal. (454 L) storage tank.

E) Controls

Stop-Start – The motor stops when the compressor unloads and starts again when the pressure in the receiver drops. Use a stop-start pressure switch control for a small system. (Compressors up to 15 hp.)

Continuous Run – Equipped with constant pressure control, loading and unloading as the supply of compressed air in the receiver drops or reaches a maximum.

Pneumatic Power Tools Have Several Advantages Over Electric Power Tools

One of the major advantages is durability, however, to make full use of that advantage some important steps must be followed.

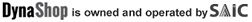

A sufficient supply of compressed air is necessary

The air system must be able to deliver an adequate volume of air and maintain the rated operating pressure at the inlet of the tool.

The supply of air must be free of contamination

The types of contamination that need to be eliminated are water (condensation produced by the temperature change while compressing the air), rust scale (rust particles produced inside iron pipes), and atmospheric dust, (dust that is pulled into the compressor from the work environment). Also, it is important to keep dust and debris from entering the air motor when the tool is disconnected from the air supply hose. Always keep the tool air inlet, hose ends, plugs and couplers clear of dust.

Lubrication (oil) through the air supply is important

Supplying oil to rotary vane air motors reduces friction and wear of the moving parts and provides protection for steel components.

Filter-Regulator-Lubricator is Recommended

As an air tool manufacturer, Dynabrade recommends the use of a Filter-Regulator-Lubricator at each tool station. We also encourage the use of correctly sized accessories that will deliver a sufficient supply of air. Some examples of Dynabrade air tool accessories are Dynaswivel® airline connectors, quick disconnect fittings, and in-line blow guns. All of these accessories make for suitable additions to any compressed air system.