Showing all 8 results

About this category

For Use on Metal, Fiberglass, Carbon Fibre, Composites and More!

Kevlar® phenolic vanes for longer life. Lightweight ergonomic design for greater comfort and control. One-piece spindle keeps all rotating components on the same centerline for reduced run-out, which means lower vibration levels for enhanced operator comfort. Front and rear exhaust models. Air passage to continually cool the gear box – gears last longer!

Showing all 8 results

For Use on Metal, Fiberglass, Carbon Fibre, Composites and More!

Features and Advantages

• Lightweight ergonomic design for greater comfort and control.

• One-piece spindle keeps all rotating components on the same centerline for reduced run-out, which means lower vibration levels for enhanced operator comfort.

• Front and rear exhaust models. Air passage to continually cool the gear box – gears last longer!

• Needle bearing assures proper shaft alignment.

• Dual wick lubrication system – saturated with gear oil for extended gear life – over 700 hours. This helps administer the right amount and keep the gear oil on the metal gears.

• Highest horsepower and torque levels of any similar competitive product.

Benefits

• We use Gear Oil as opposed to grease. Gear Oil is specially formulated to STICK TO METAL. Grease does not stick and the centrifugal force of the spinning gears throws the grease away from the metal surface.

• Longer gear life means reduced downtime and less costly repairs.

• Front and rear exhaust models – user can decide which configuration is right for them. More choice means more control of their purchase.

• Lower vibration levels help prevent worker injuries such as Carpal Tunnel Syndrome. Machines are easier to use because they do not “buzz” in your hands. Workers can use smooth running machines longer.

• Low profile machines are ideal for “hard-to-reach” areas. A performance plus!

• All machines are perfectly compatible with all Dynabrade Accessories.

Providing systemized solutions for our customers is a key to

Dynabrade’s success.

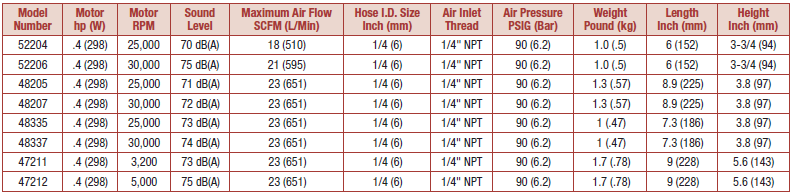

Front Exhaust Models

Model 52204 – 25,000 RPM, 1/4″ & 6 mm Collets

Model 52206 – 30,000 RPM, 1/4″ & 6 mm Collets

Rear Exhaust Models with Extended Muffler

Model 48205 – 25,000 RPM, 1/4″ & 6 mm Collets

Model 48207 – 30,000 RPM, 1/4″ & 6 mm Collets

Rear Exhaust Models with Standard Muffler

Model 48335 – 25,000 RPM, 1/4″ & 6 mm Collets

Model 48337 – 30,000 RPM, 1/4″ & 6 mm Collets

Rear Exhaust Models with Extended Muffler (Slow Speed)

• Both models are planetary geared.

• Slow speeds allow additional use as buffer/polisher.

Model 47211 – 3,200 RPM, 1/4″ & 6 mm Collets

Model 47212 – 5,000 RPM, 1/4″ & 6 mm Collets